Posted by Chris Case [108.247.147.90] on Sunday, November 01, 2015 at 08:25:44 :

In Reply to: Camshaft Grinds posted by John S [108.3.93.3] on Sunday, November 01, 2015 at 07:22:41 :

Headers an intake didn't help until I went to a bigger carb. Even a bigger one bbl would help a LOT.

But I think the biggest limitation is valve float from weak springs, and a cam with actual negative overlap.

From my experience as an engine mechanic at The Dyno Shop in Santee Ca., a torquer cam will lose a couple thousand rpms off the top, and gain a couple hundred on the bottom end. I would go approximatly to a stock cam grind for anydamn engine from the 70s. I haven't found any discussion on the net except the HAMB about tractor pulls, but no cam specs mentioned. The only thing I ever did was have one ground to '58 passenger car specs, little or no improvement, but old springs were re-used.

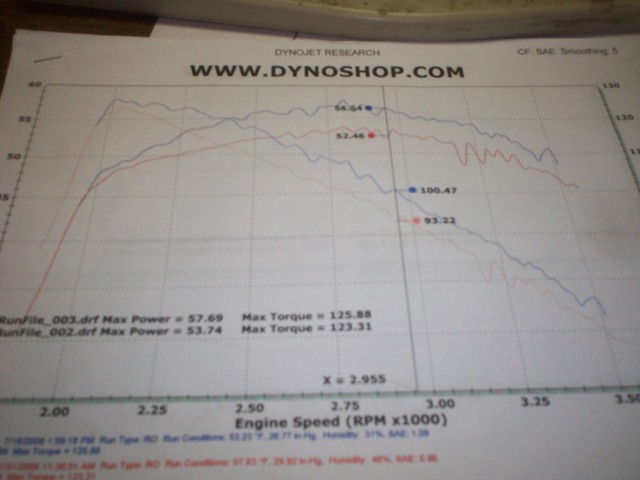

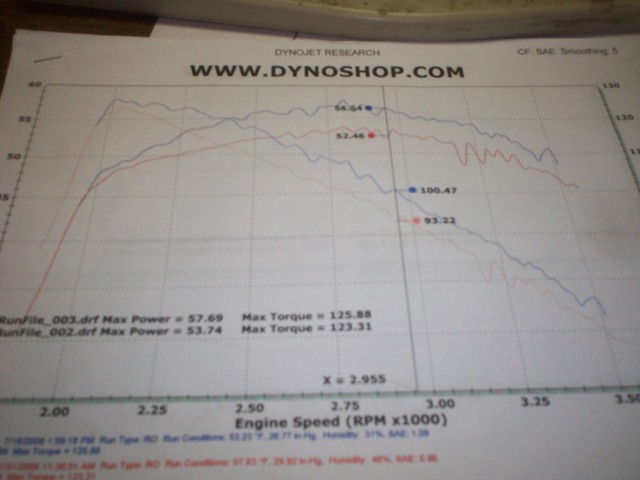

And I seem to be the only fool on the entire internet to dyno a PW.

The dyno run pictured is headers and intake, NOT latest and greatest head #, and one bbl vs 2bbl. Plus I recurved the dist by seat of the pants, probely dist in and out 20 times. It ended up close to the stock curve, but initial bumped up to 10°. 105# cranking comp. Note the improvement is across the powerband, up to 3250rpm. Cam and springs would make a really big difference. Those tractor pull guys do 5,000rpm with huge cam.

Follow Ups: